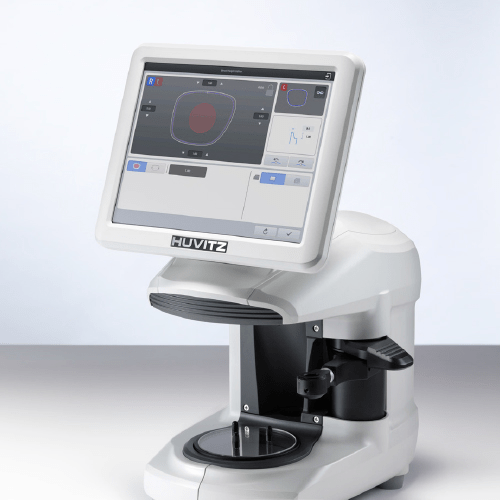

HPE-990

Lens Edger

High-end lens edger that produces any lens with stability, minimizing axis deviation risks

- Unwavering Stability in Every Cut

- World’s First Lens-Over-Frame Sunglass Processing

- High-Quality Results with Precision Processing

- Powerful Performance, Faster Work Speed

Explore Details

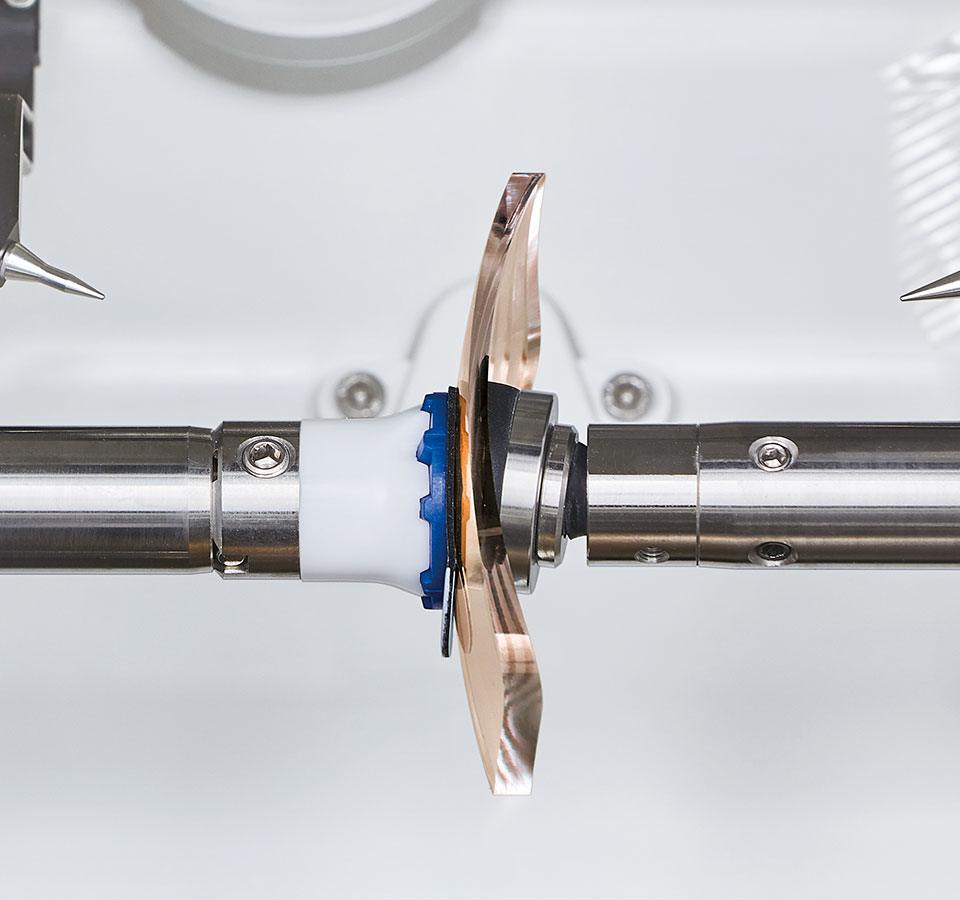

Unwavering Stability in Every Cut

With the more powerful 1,250W 5,000 rpm wheel motor, the newly designed Xtra Large clamp, and the expanded block adapter, HPE-990 ensures stable processing of all lenses, including ultra-hydrophobic and high curvature specialty lenses, as well as coated lenses. Especially in the ultra-hydrophobic lens processing mode, HPE-990 adjusts the processing axis through settings like clamp pressure and rotation speed, allowing for precise and flawless processing of any lens.

World’s First Lens-Over-Frame Sunglass Processing

The HPE-990 is the first edging machine capable of producing lens-over-frame sunglasses, a trend observed in house brands and more. Specially designed for Deep Step Bevel processing up to a maximum depth of 20mm, it allows easy and convenient manufacturing of various complex shapes, including swimming goggles and other specialty designs.

High-Quality Results with Precision Processing

With the ability to process high curves up to Base 10, a built-in Concave Semi-T drill, and Scan&Cut support, HPE-990 precisely handles even the most challenging eyewear frames, such as high-curvature goggles and sports sunglasses. The advanced processing technology ensures high-quality results with exceptional precision.

Powerful Performance, Faster Work Speed

With the enhanced 1,250W 5,000 rpm high-strength power motor wheel, the cutting speed has significantly improved, and the drill work speed has also increased thanks to the high-speed spin. The HPE-990, the fastest among Huvitz edging machines, delivers fast and efficient performance.

Specifications

Lens Material

Plastic, High index plastic, Polycarbonate, Trivex, Glass

Edging Type

Bevel, Mini bevel, Partial bevel, Asymmetric bevel, Semi-U bevel, Step bevel, Deep step bevel,

Groove, Partial groove, Dual groove, Hybrid groove, Rimless

Edging Position

Front %, Front mm, Rear mm, Base curve, Auto, Manual (with 2D simulation and 3D preview)

Edging Options

Polishing, Safety bevel, Safety mode

Built-in Drilling

Hole, Slot, Notch, Scan & Cut (custom shape), Chemistrie Clip

Functions

Job manager, Digital pattern,

Hole editor, Asymmetric bevel editor, Scan & Cut shape editor, Step bevel editor,

OMA import/export, CAD import/export, DCS/OMA compatibility,

Retouch mode (Normal, Drill-only, All)

Job Support

Half Jacket, Full Jacket (up to 6 base and 6 mm in depth),

Custom shape (Scan&Cut),

Chemistrie Clip,

Lens-Over-Frame sunglasses,

Swimming goggles,

VR Rx inserts

Utilities

LCD tilting,

Automatic edging room door,

Edging room illumination, Status LED,

USB memory,

Barcode reader interface, Vacuum interface

Edging Size

Max. 90 mm,

Min. flat edging: 18.5 mm (without safety bevel),

Min. bevel edging: 20 mm (without safety bevel)

Display

9.7" color TFT LCD (1024x768) with touch screen

Dimensions / Weight

540(W) x 465(D) x 590(H) mm / 51 kg

Power Supply

AC 100–120 V / AC 210–230 V 50/60 Hz

Power Consumption

100–120 V ~ 50/60 Hz 1275 VA, 210–230 V~ 50/60 Hz 2060 VA

Product Type

Step Bevel

Deep Step Bevel

Built-in Drill

PRO

RPDA***

O

O

O

XD

RPA*, RPGA**

O

X

O

X

RPA, RPGA

O

X

X

D

RPA, RPGA

X

X

O

N

RPA, RPGA

X

X

X

* RPA type comprises high-speed super wide roughing wheel and hybrid finishing wheel.

** RPGA type comprises high-speed roughing wheel, glass wheel and hybrid finishing wheel.

*** RPDA type comprises high-speed super wide roughing wheel, hybrid finishing wheel and deep step bevel wheel.

Lens Material

RPDA

RPA

RPGA

Plastic

O

O

O

Hi-index

O

O

O

Polycarbonate

O

O

O

Trivex

O

O

O

Glass*

X

X

O

* Glass lens is not supported with grooving, polishing, step beveling, and drilling.

Edging Type

RPDA

RPA

RPGA

Mini bevel

0.1 ~ 0.8

Asymmetric bevel

Front: 0.1~0.8, Rear: 0.1~2.5

Semi-U bevel

Width: 0.1~1.0, Rear: 0.1~2.5

Bevel polishing

X

O

X

Combined edging

Partial bevel, Partial groove, Dual groove, Hybrid groove

High base bevel

~ 10

~ 7

~ 7

Specification and design are subject to change without notice.

5. Power Consumption

15W(Max)

Related Products

FAQ

Q. What is the greatest strength of the HPE-990?

A. The greatest strength of the HPE-990 lies in its ability to process any type of lens with exceptional stability. Powered by a 1,250W, 5,000 rpm high-performance wheel motor, along with a newly designed Xtra Large clamp and an expanded block adapter, it ensures vibration-free processing. Even highly hydrophobic and high-curvature lenses can be handled reliably, delivering a high level of finishing quality even for the most demanding jobs.

Q. What technology allows the HPE-990 to be the world’s first machine capable of processing “lens-over-frame sunglasses”?

A. The HPE-990 applies Deep Step Bevel processing technology capable of achieving depths of up to 20 mm, making it the world’s first edger able to process “lens-over-frame sunglasses,” a popular trend among house brands. This technology enables precise machining of deep steps and complex structures, allowing lens-over-frame sunglasses—difficult to process with conventional equipment—to be produced stably and accurately.

Q. What level of precision and performance does the HPE-990 offer?

A. The HPE-990 supports Base 10 high-curve processing, a concave Semi-T built-in drill, and Scan & Cut functions, enabling precise processing of challenging frames such as high-curve goggles and sports sunglasses. In addition, the 1,250W 5,000 rpm power motor wheel and high-speed spin drill significantly enhance both speed and accuracy in cutting and drilling operations.

Q. What types of frames is the HPE-990 best suited for?

A. The HPE-990 is especially suitable for frames that are difficult to process with standard equipment, such as lens-over-frame sunglasses, high-curve goggles, sports sunglasses, flat bar and Half Jaket. Its ability to precisely implement deep steps and complex curvatures allows stable processing even for frames with intricate shapes.

Q. What advantages does the HPE-990 offer when processing highly hydrophobic coated lenses?

A. The HPE-990 provides outstanding stability when processing highly hydrophobic coated lenses. With its powerful 1,250W 5,000 rpm wheel motor, newly designed Xtra Large clamp, and expanded block adapter, even difficult hydrophobic lenses can be processed without slippage or instability. In particular, the dedicated hydrophobic lens mode automatically optimizes clamp pressure and rotation speed, enabling an even higher level of finishing quality.

Inquiry

We look forward to your inquiry. please let us know what we can help you with, and we will get back to you as soon as possible.

지금 바로 카탈로그를 다운로드하여

제품의 주요 특징과 혜택을 확인해 보세요.

지금 바로 카달로그를 확인해 보세요.

제품의 주요 특징과 혜택을 한눈에 볼 수 있습니다.

Download our catalog now to uncover all the key features and benefits of our products.

View our catalog now to explore the key features and benefits of our products.

Do you have any questions about the product?

Are you looking for dealer information?

Inquiry

Curious about Huvitz? Kindly leave your contact information, and we will be happy to provide you with prompt and helpful answers.

휴비츠에 대해 궁금한 점을 남겨주시면 빠르게 답변드리겠습니다.

Service & Support

Need assistance with a Huvitz product? Leave your contact information, and we will provide you with prompt and helpful assistance.

휴비츠 제품 관련 지원이 필요하신가요? 연락처 정보를 남겨주시면 신속하고 정확하게 안내해 드리겠습니다.

The Huvitz Chat bot is currently under preparation.

We are working hard to provide our customers with better quality services.

Let’s find a perfect match with Huvitz!

The Huvitz Members site is currently under preparation.

We are working hard to provide our customers with better quality services.