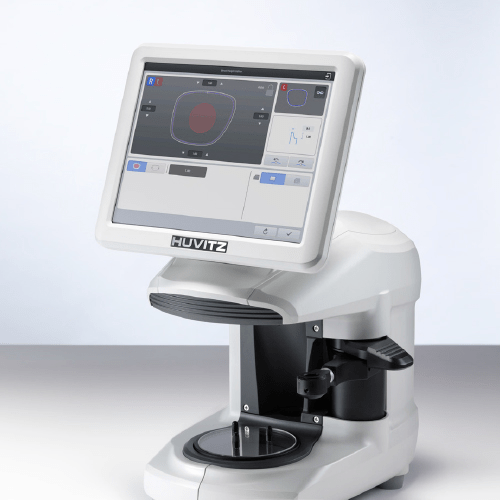

HBK-410

New Smart Blocker

Lens blocker that that quickly recognizes lenses and blocks them stably and accurately

- Quickly and clearly recognizes 3-Dot and laser marks

- Provides stable and accurate blocking

- Allows for one-step lens adapter attachment

MENU

Explore Details

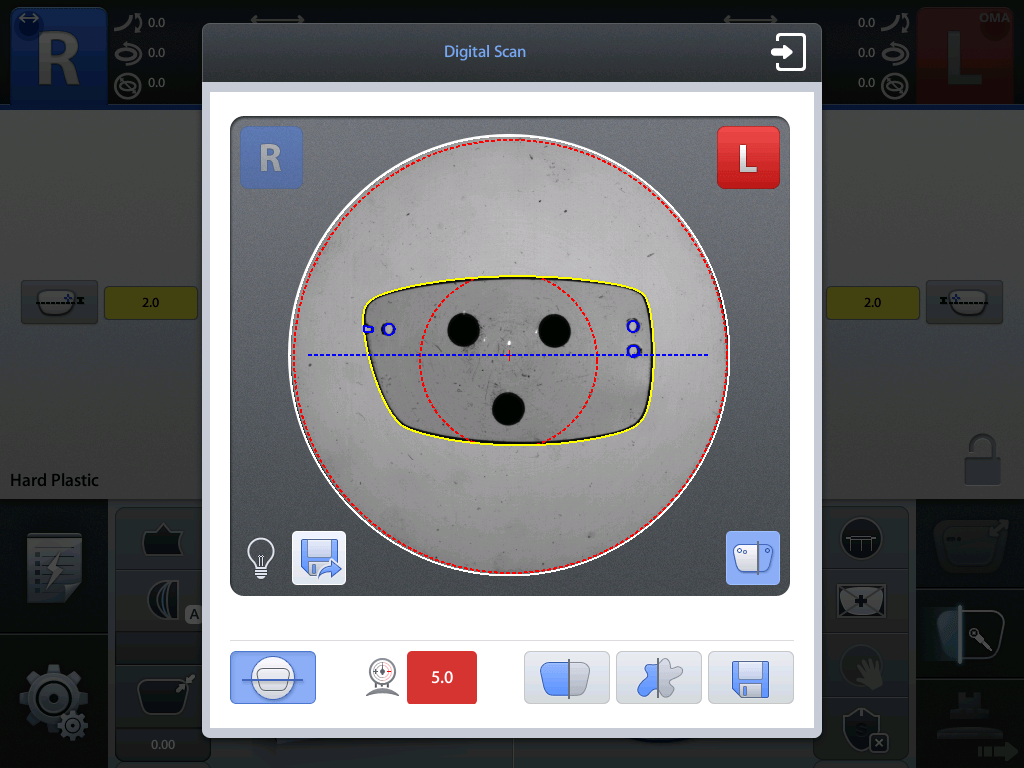

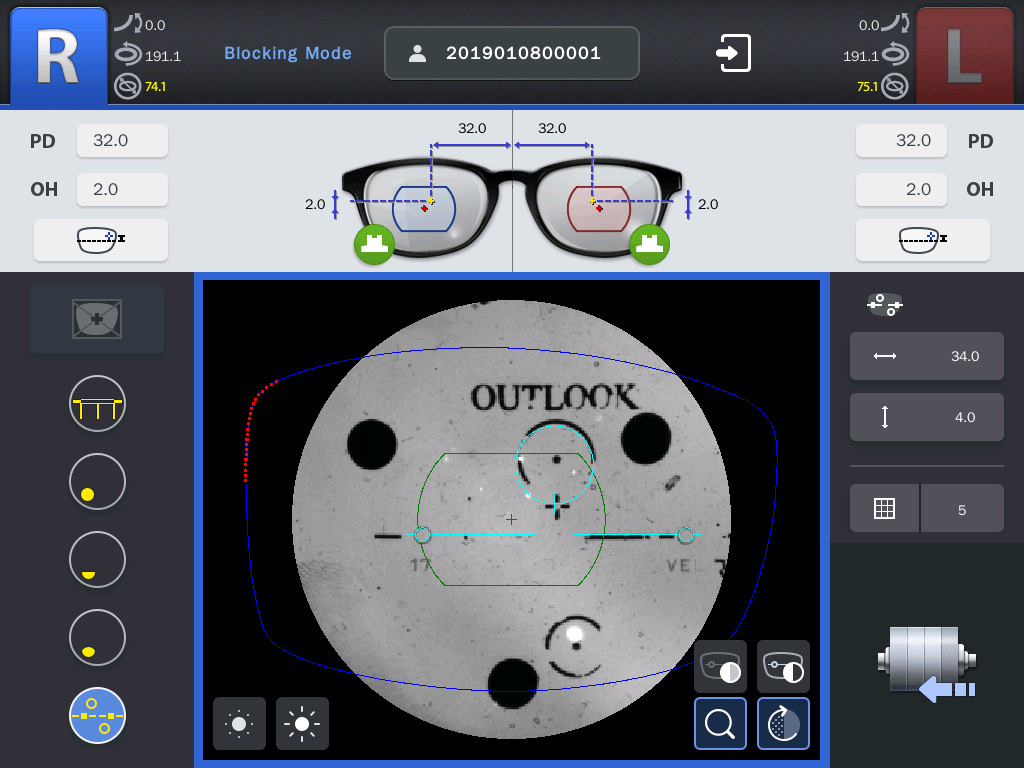

Quickly and clearly recognizes 3-Dot and laser marks

Digital scan recognizes frame shapes, drill holes and creative shapes. High resolution & sharp imaging capability help recognize laser markings.

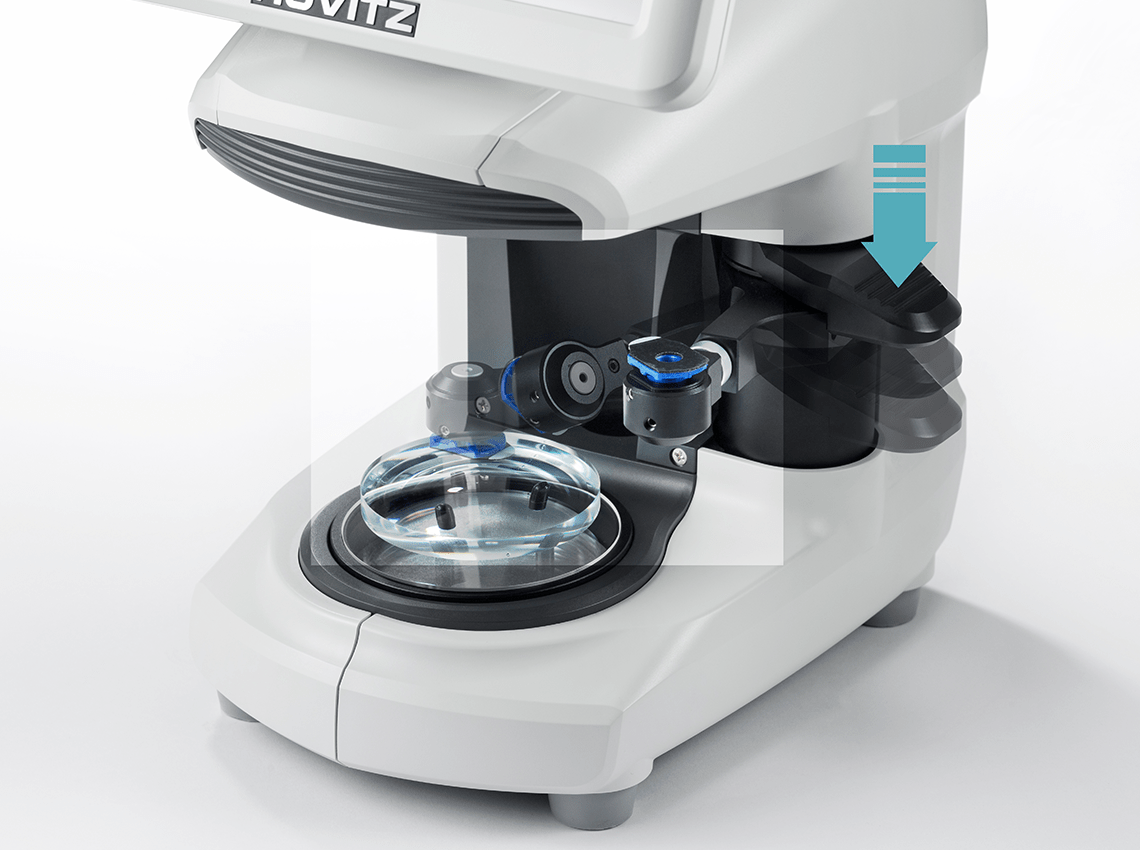

Provides stable and accurate blocking

The blocking process is made stable by pressing the arm lever instead of manually rotating the blocker arm. Additionally, inputting additional values through the screen automatically adjusts the blocking position.

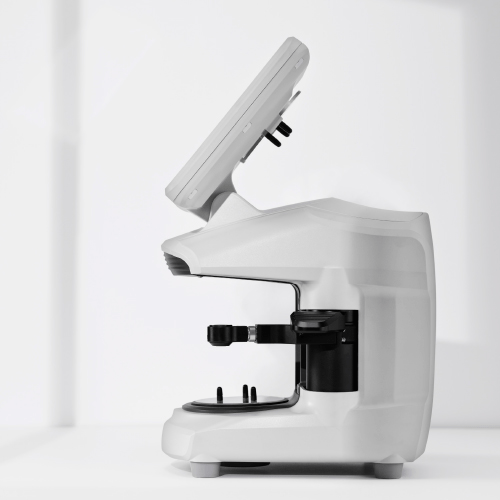

Allows for one-step lens adapter attachment

Mounting the lens adapter from the top allows for easier and more convenient attachment

Video

Huvitz MEMBERS

더 많은 안과컨텐츠를 원하신다면

휴비츠멤버스에 가입하세요.

Specifications

1. Blocking

Blocking Method

Manual (Push down)

Blocking Mode

Box center, Optical center

Blocking Guide

3-Dot, Bi-focal, Progressive

Blocking Assistance

Laser mark visualization, PD/OH live adjustment

Lens shortage check, Block attachment check

Auto Brightness control, Camera zoom

Blocking Tolerance

±0.5mm

Axis Tolerance

±1°

2. Digital Scan

Frame shape, Hole/Slot/Notch, Scan & Cut shape

3. Layout

Layout Factors

FPD, PD(Binocular, Monocular)

DBL, OH/V, Boxed height, Mixed height, Centering

Method(Box center, Optical center)

4. Edging

Edging Factors

Lens material (Plastic, Polycarbonate, High index, Glass, Trivex)

Edging Type (Bevel, Groove, Flat, Mini bevel, Partial bevel, Partial grooving, Dual grooving, Hybrid grooving, Asymmetric bevel, Semi-U bevel, Step bevel)

Edging Position (Front %, Front mm, Rear mm, Base curve, Auto, Manual)

Edging Option (Polishing, Safety bevel, Safety mode)

5. Edging Functions

Functions

Job Manager, Digital Pattern, Hole Editor, Asymmetric Bevel Editor, Step Bevel Editor, Scan & Cut Data Editor, Image File Converter, OMA Import/Export, CAD(DXF) Import/Export, R-L shape correction, Lens diameter measurement, Auto save & transmission of job files

6. Hardware Specification

Utilities

Tiltable LCD (Viewing angle 15~70°)

SD card storage of 16GB(Support up to 32GB)

Barcode reader interface

Display

9.7 inch Color TFT LCD (1024x768) with Touch Screen

Dimensions / Weight

236(W) x 268(D) x 422(H)mm / 8kg

Power Supply

AC 100~240V 50/60Hz

Power Consumption

20W

* Specification and design are subject to change without notice.

Related Products

FAQ

Q. What are the key features of the HBK-410 lens blocker?

A. The HBK-410 supports accurate blocking through its Smart Digital Scan function, which quickly and clearly recognizes frame shapes, drilling positions, and laser marks on progressive lenses. It is designed to perform blocking by pressing an arm lever rather than manually rotating the blocker arm, ensuring more stable blocking without vibration during operation.

Q. What level of precision (tolerance) does the HBK-410 guarantee for blocking and axis alignment?

A. The HBK-410 guarantees a blocking tolerance of ±0.5 mm and an axis tolerance of ±1°. This high level of precision minimizes deviation of the lens center and axis from the set position, helping maintain accurate and consistent processing quality.

Q. Does the HBK-410 support data storage or connection to external devices?

A. Yes. The HBK-410 is equipped with a built-in 16 GB SD card, expandable up to 32 GB, allowing stable storage of job files. It also supports a barcode reader interface, enabling quick input of job information through an external barcode reader.

Q. Who is the HBK-410 suitable for?

A. The HBK-410 allows even beginners to perform accurate blocking by clearly recognizing three reference points through Smart Digital Scan, without the need to visually locate marking points. Its stable, vibration-free blocking process and one-touch lens block attachment make it particularly suitable for optical shops and lens processing workshops that require fast and precise operations.

Q. How is blocking stability ensured on the HBK-410?

A. Blocking stability is ensured through a design that performs blocking by pressing an arm lever instead of rotating the blocker arm, eliminating vibration during operation. In addition, once the required values are entered on the screen, the device automatically adjusts the blocking position, enabling even inexperienced users to achieve accurate and consistent results.